Introduction to CNC Machines

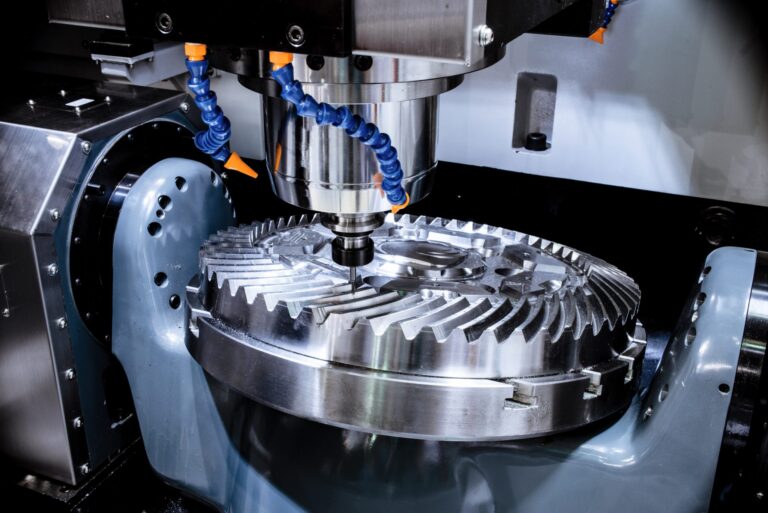

CNC machines have revolutionized the manufacturing industry, allowing for precise and efficient production processes. But what exactly is the system used by CNC machines? Let’s find out.

Overview of CNC Machines and their importance

CNC stands for Computer Numerical Control, which refers to the automation of machine tools through the use of computer programs. These programs control the movement and operation of the machine, ensuring accuracy and consistency in the manufacturing process.

The system used by CNC machines involves a combination of hardware and software. The hardware includes motors, sensors, and actuators that control the movement of the machine’s components. The software, on the other hand, consists of a computer program that translates design specifications into machine instructions.

The importance of CNC machines lies in their ability to produce complex and precise parts with minimal human intervention. They offer numerous advantages such as increased productivity, improved efficiency, and reduced errors. CNC machines are widely used in industries such as aerospace, automotive, and electronics, where precision and quality are paramount.

In conclusion, CNC machines utilize a system that combines computer programming with hardware components to automate manufacturing processes. Their importance cannot be overstated in today’s competitive manufacturing landscape.

Basics of CNC Machining

Understanding the fundamentals of CNC Machining

CNC machines have revolutionized the manufacturing industry, providing precise and efficient solutions for various applications. But what system do these machines use to operate?

CNC stands for Computer Numerical Control, which means that these machines are controlled by computer programs. The system used by CNC machines involves a combination of hardware and software components.

At the heart of the system is a computer that runs specialized software, known as CAD/CAM software. This software allows operators to design and program the desired part or component. The program is then converted into a format that the CNC machine can understand, typically using G-code.

The hardware components of a CNC machine include motors, drives, and controllers. These components work together to move the cutting tools or workpiece with precision according to the programmed instructions.

The CNC machine reads the program line by line, executing each command to perform the required machining operations. The machine’s movements are controlled by servo motors, which receive signals from the controller and adjust their position accordingly.

Overall, the system used by CNC machines combines computer programming, specialized software, and hardware components to automate and control the machining process. This allows for greater accuracy, repeatability, and efficiency compared to traditional manual machining methods.

In conclusion, CNC machines utilize a computer numerical control system that integrates software and hardware components to execute precise machining operations.

Computer-Aided Design (CAD)

Explaining the role of CAD in CNC Machines

CNC machines are revolutionizing the manufacturing industry by automating processes and improving precision. But what system do these machines use to carry out their operations? The answer lies in Computer-Aided Design (CAD).

CAD is a software technology that allows designers and engineers to create detailed digital models of products or parts. These models serve as the foundation for CNC machines to understand and execute the necessary machining instructions. The CAD software enables users to design complex shapes, dimensions, and specifications with precision and accuracy.

Once the design is complete, the CAD software generates a digital file that contains all the necessary information for the CNC machine to produce the desired part. This file includes details such as tool paths, cutting depths, and feed rates.

The CNC machine reads this digital file and translates it into a series of precise movements and actions. It controls the machine’s motors, tools, and other components to carve, cut, or shape the raw material into the final product.

In summary, CAD plays a vital role in CNC machines by providing the necessary instructions and specifications for manufacturing. It allows designers to create intricate designs with ease and ensures that the CNC machine produces accurate and high-quality parts.

Computer-Aided Manufacturing (CAM)

Explaining the role of CAM in CNC Machines

When it comes to CNC machines, one might wonder what system is used to control their operations. The answer lies in Computer-Aided Manufacturing (CAM).

CAM is a software system that plays a crucial role in CNC machines. It takes the design specifications created in Computer-Aided Design (CAD) software and translates them into instructions that the CNC machine can understand. These instructions include details such as tool paths, cutting speeds, and feed rates.

The CAM software uses algorithms to optimize the machining process, ensuring efficient and accurate production. It enables the creation of complex designs and intricate patterns that would be difficult to achieve manually.

By utilizing CAM software, CNC machines can produce consistent and high-quality products with minimal human intervention. This automation reduces the risk of errors and increases productivity.

In summary, CAM is the system used by CNC machines to convert design specifications into machine instructions. It plays a vital role in streamlining the manufacturing process, enabling precise and efficient production.

G-code Programming

Understanding the G-code programming language used in CNC Machines

CNC machines are widely used in manufacturing industries for their precision and efficiency. But have you ever wondered what system these machines use to operate? The answer lies in the G-code programming language.

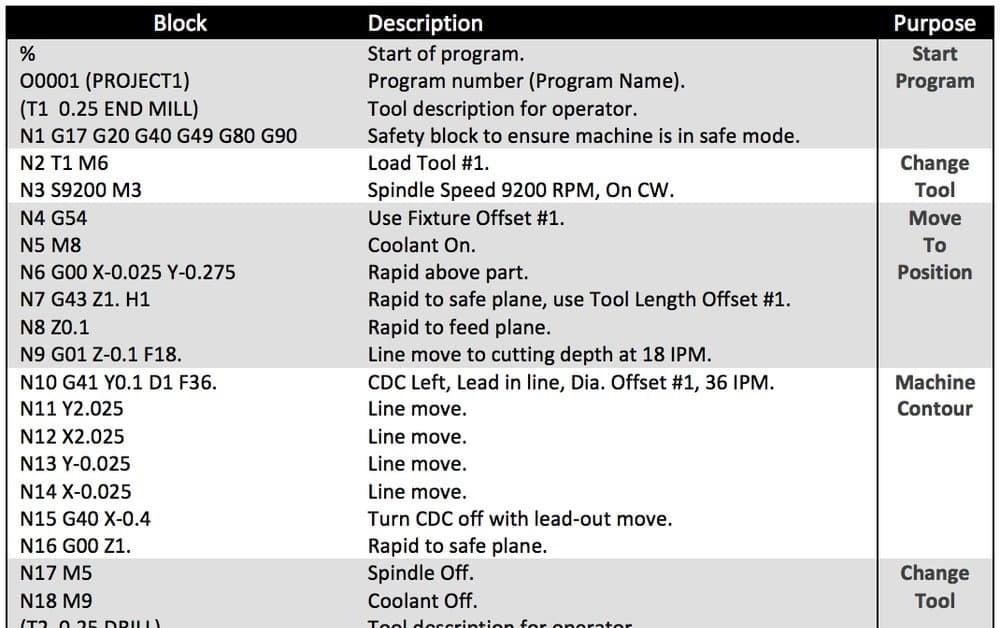

G-code is a standardized programming language that is used to control the movements and functions of CNC machines. It consists of a series of commands, known as G-codes, which are interpreted by the machine’s controller.

The G-codes specify various parameters such as tool movements, feed rates, spindle speeds, and coolant control. These codes are written in a specific format and can be customized to suit the specific requirements of the machine and the task at hand.

Understanding G-code programming is essential for anyone working with CNC machines. It allows operators to create complex designs, control the machine’s movements, and optimize production processes.

While learning G-code programming may seem daunting at first, there are resources available online and training programs that can help individuals master this language. With practice and experience, operators can harness the full potential of CNC machines and unlock endless possibilities in manufacturing.

So, whether you are a beginner or an experienced operator, investing time in understanding G-code programming will undoubtedly enhance your skills and make you more proficient in operating CNC machines

Control Systems in CNC Machines

Exploring the different types of control systems used in CNC Machines

CNC machines are revolutionizing the manufacturing industry with their precision and efficiency. But have you ever wondered how these machines are controlled? Let’s take a closer look at the different types of control systems used in CNC machines.

- Open-loop control system: This type of control system operates based on predetermined commands without any feedback. It is simple and cost-effective but lacks accuracy and adaptability.

- Closed-loop control system: Unlike open-loop systems, closed-loop control systems use feedback to continuously monitor and adjust the machine’s performance. This ensures greater accuracy and reliability, making it ideal for complex machining operations.

- Computer Numerical Control (CNC): CNC is a sophisticated control system that utilizes computer software to automate and control the machine’s movements. It allows for precise control over multiple axes simultaneously, enabling complex shapes and designs to be produced with ease.

- Direct Numerical Control (DNC): DNC is a centralized control system where a main computer controls multiple CNC machines simultaneously. It eliminates the need for individual programming on each machine, streamlining production processes and improving efficiency.

- Distributed Numerical Control (DNC): Similar to DNC, distributed numerical control also involves a central computer controlling multiple machines. However, in this case, each machine has its own local computer that communicates with the central computer, allowing for greater flexibility and autonomy.

In conclusion, CNC machines employ various control systems to ensure precise and efficient operations. Understanding these control systems can help businesses choose the right CNC machine for their specific manufacturing needs.

CNC Machine Tools and Components

Overview of the various tools and components used in CNC Machines

CNC machines, or Computer Numerical Control machines, are widely used in manufacturing industries for their precision and efficiency. These machines rely on a system that controls their movements and operations. The key components of a CNC machine include the control panel, motors, drive systems, and cutting tools.

The control panel is where the operator inputs the instructions for the machine. It allows for precise control over the movements and operations of the machine. The motors are responsible for driving the different axes of the machine, enabling it to move in multiple directions.

The drive systems transmit power from the motors to the various moving parts of the machine. They ensure smooth and accurate movement of the machine during operation. Lastly, the cutting tools are essential for shaping and machining the workpiece. These tools can include drills, mills, lathes, and routers, among others.

Overall, CNC machines rely on a sophisticated system that combines these components to execute precise and complex operations. The use of computer control allows for automation and repeatability in manufacturing processes, resulting in increased productivity and accuracy.

In conclusion, understanding the tools and components used in CNC machines is crucial for anyone working with or interested in this technology. By familiarizing yourself with these components, you can better appreciate the capabilities and advantages of CNC machines in various industries.

Advantages and Applications of CNC Machines

Highlighting the advantages and wide-ranging applications of CNC Machines

CNC machines, or Computer Numerical Control machines, are a type of automated machinery that use computer programming to control their operations. They have revolutionized the manufacturing industry with their precision, efficiency, and versatility.

One of the main advantages of CNC machines is their ability to produce highly accurate and consistent results. The computer programming allows for precise control of the machine’s movements, resulting in parts and products that meet tight tolerances. This level of precision is especially valuable in industries such as aerospace, automotive, and medical, where quality and reliability are paramount.

Another advantage of CNC machines is their efficiency. Once the program is set up, the machine can run continuously without the need for constant human intervention. This not only saves time but also reduces the risk of errors caused by human factors.

The applications of CNC machines are vast and varied. They can be used for cutting, shaping, drilling, milling, and even 3D printing. From creating intricate metal components to carving wood or engraving designs on surfaces, CNC machines offer endless possibilities.

In conclusion, CNC machines offer numerous advantages in terms of precision, efficiency, and versatility. Their wide-ranging applications make them indispensable in various industries. Whether you are a small business or a large manufacturing company, investing in CNC machines can significantly enhance your production capabilities and overall efficiency.

Conclusion

In conclusion, CNC machines are widely used in various industries due to their precision, efficiency, and versatility. These machines operate using a computer numerical control system, which allows for automated and accurate machining processes. By using CNC machines, businesses can benefit from increased productivity, reduced labor costs, improved quality control, and the ability to create complex and intricate designs.

Summing up the importance and benefits of CNC Machines

The importance and benefits of CNC machines can be summarized as follows:

- Precision: CNC machines offer high levels of precision and accuracy in machining operations, ensuring consistent and reliable results.

- Efficiency: These machines can perform tasks at a faster rate compared to manual machining methods, leading to increased productivity.

- Versatility: CNC machines can be programmed to perform a wide range of tasks, making them suitable for various industries and applications.

- Cost-effectiveness: While the initial investment may be higher, CNC machines can reduce labor costs in the long run by automating processes and minimizing errors.

- Quality control: With CNC machines, businesses can maintain consistent quality standards as the machines follow programmed instructions precisely.

FAQ (Frequently Asked Questions)

- What does CNC stand for?

CNC stands for Computer Numerical Control. - What industries use CNC machines?

CNC machines are used in industries such as aerospace, automotive, manufacturing, woodworking, and medical, among others. - Can CNC machines be used for prototyping?Yes, CNC machines are commonly used for prototyping due to their ability to produce accurate and detailed parts.

- Are CNC machines difficult to operate?While operating a CNC machine requires training and programming skills, modern systems have user-friendly interfaces that make them easier to operate.

- Can CNC machines be customized?Yes, CNC machines can be customized to meet specific requirements by programming them accordingly.