Understanding CO2 Laser Machines and CNC Machines

Overview of CO2 Laser Machines

CO2 Laser machines utilize a high-powered laser to cut or engrave materials with precision. They are commonly used in industries for tasks such as cutting wood, acrylic, and metal. The laser beam is generated in a tube filled with CO2 gas, which is then directed through mirrors to focus the beam onto the material’s surface.

Overview of CNC Machines

CNC (Computer Numerical Control) machines are automated tools that operate through programmed commands. They can perform various tasks such as cutting, milling, and drilling with high accuracy and efficiency. CNC machines are widely used in manufacturing processes to create complex parts and components. These machines are controlled by computers that translate design specifications into precise movements of the tool.

CO2 Laser Technology

How CO2 Laser Machines Work

CO2 Laser machines operate by employing a high-powered laser beam produced from CO2 gas-filled tubes. This laser beam is then focused through mirrors to cut or engrave materials with extreme precision.

Applications of CO2 Laser Technology

CO2 Laser technology finds extensive use in various industries for cutting and engraving materials like wood, acrylic, and metal. These machines are favored for their ability to deliver intricate and accurate results, making them valuable tools in manufacturing and design processes.

CNC Machine Technology

How CNC Machines Work

CNC machines utilize computer numerical control to precisely control the tools and machinery in manufacturing processes. These machines follow programmed instructions to cut, drill, or shape various materials with high accuracy and repeatability. CNC machines operate by interpreting design files and translating them into movements of cutting tools along multiple axes.

Applications of CNC Machine Technology

CNC machine technology is widely applied across industries such as automotive, aerospace, and electronics for tasks like milling, turning, and routing. These machines fabricate complex components from materials like metals, plastics, and composites, ensuring consistency in production and minimizing human error. CNC technology enhances productivity and efficiency in manufacturing processes.

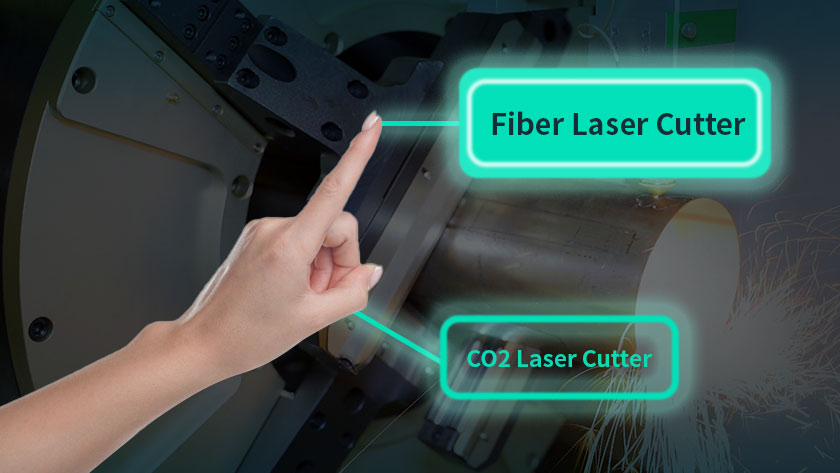

Key Differences Between CO2 Laser and CNC Machines

Distinguishing Features of CO2 Laser Machines

– Use high-powered CO2 lasers for cutting and engraving materials like wood, acrylic, and leather.- Provide precise and clean cuts with minimal material wastage.- Ideal for intricate designs and detailed work due to their high level of precision.- Commonly used in industries like signage, custom gift making, and prototyping.- Higher initial investment cost but cost-effective for high-volume production.

Distinguishing Features of CNC Machines

– Utilize computer numerical control for tasks like cutting, drilling, and shaping various materials.- Suitable for a wide range of materials including metals, plastics, and composites.- Offer high accuracy and repeatability in production processes.- Widely used in industries such as automotive, aerospace, and electronics for fabricating complex components.- Provide enhanced productivity and efficiency in manufacturing operations.

Pros and Cons of CO2 Laser Machines

Advantages of CO2 Laser Machines

– CO2 laser machines offer precise cutting and engraving capabilities on materials like wood, acrylic, and leather.- They excel in creating intricate designs with high precision and minimal material wastage.- Ideal for industries like signage, gift making, and prototyping due to their detailed work output.- Cost-effective for high-volume production despite higher initial investment.- Versatile in application and customizable for various design needs.

Disadvantages of CO2 Laser Machines

– Limited in cutting metals and reflective materials effectively.- Maintenance and operating costs can be relatively high.- The need for proper ventilation and safety measures due to the emission of fumes.- Initial setup and training required for optimal usage.- Not suitable for large-scale industrial manufacturing processes.

Conclusion

Final Thoughts on the Distinction between CO2 Laser and CNC Machines

In evaluating the use of CO2 laser machines, it is evident that they offer precise cutting and engraving capabilities on various materials, making them ideal for industries like signage and prototyping. While excelling in intricate designs with minimal wastage, they do have limitations in cutting metals and reflective materials effectively. Additionally, the maintenance costs and need for proper ventilation may pose challenges. On the other hand, CNC machines offer versatility in material processing but may lack the precision of CO2 lasers for detailed work. Understanding the specific needs of a project is crucial in determining which machine would be most suitable for efficient production.