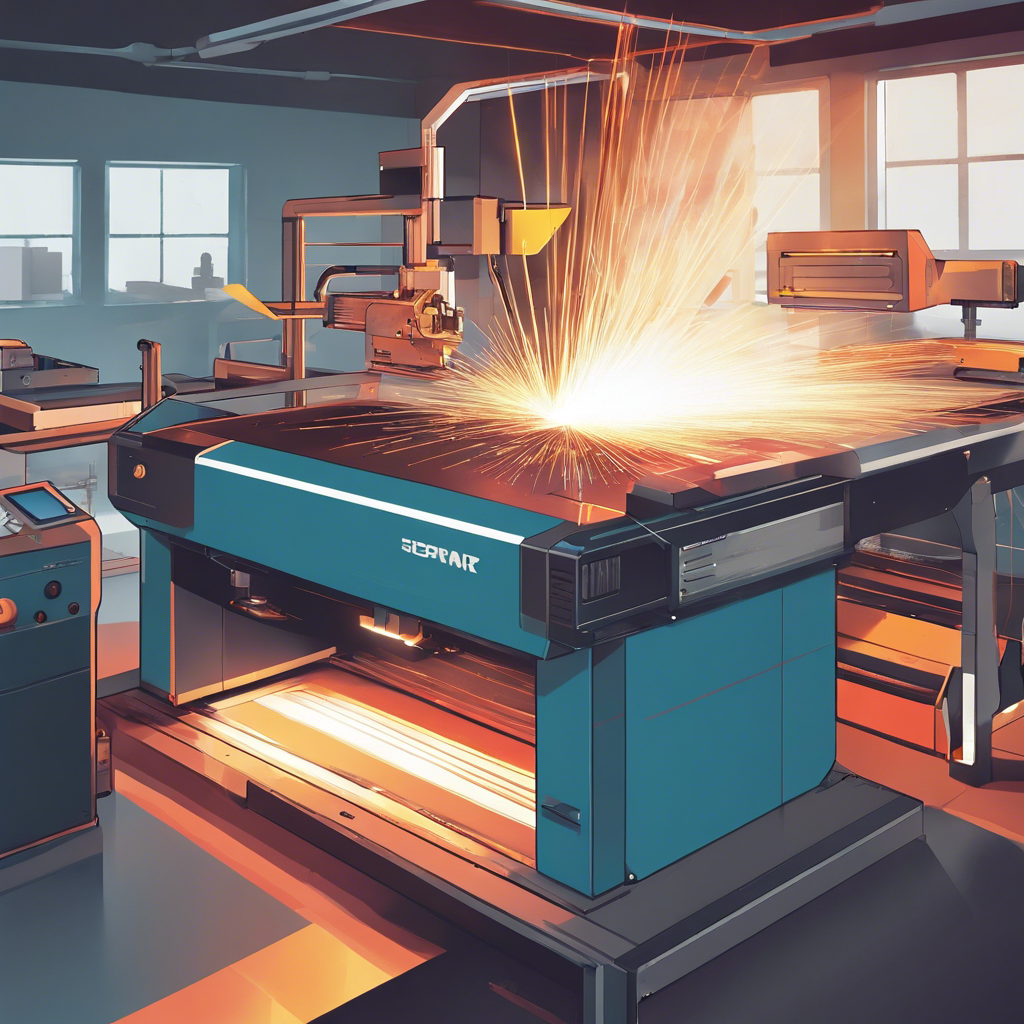

CNC laser machines have revolutionized the manufacturing industry with their ability to transform design concepts into tangible products. These machines utilize advanced laser technology to cut, engrave, and shape a wide variety of materials with precision and accuracy. The impact of CNC laser machines has been profound, as they offer numerous advantages such as increased productivity, improved efficiency, and enhanced quality control. In this article, we will explore the working principles of CNC laser machines, their applications, and the future prospects of this technology in shaping the manufacturing industry.

Overview of CNC laser machines and their impact on the industry

CNC laser machines have brought significant advancements to the manufacturing industry. These machines utilize laser technology to cut, engrave, and shape materials with precision and accuracy. The impact of CNC laser machines is evident in various sectors, including automotive, aerospace, and jewelry. They have revolutionized production processes by increasing productivity, improving efficiency, and ensuring consistent quality control. CNC laser machines are reshaping the industry by enabling faster turnarounds, reducing costs, and pushing the boundaries of design possibilities.

Advantages of using CNC laser machines in manufacturing processes

CNC laser machines offer numerous advantages in manufacturing processes. They provide high precision and accuracy, ensuring consistent quality control. These machines have faster turnaround times and increased productivity, leading to improved efficiency. CNC laser machines can work with a variety of materials, including metals and plastics, making them versatile for different industries. They also reduce waste and material costs, contributing to cost savings in production.

Understanding CNC Laser Machines

CNC laser machines are highly sophisticated tools used in manufacturing processes. These machines use a computer-controlled system to guide a laser beam, which is directed onto a material, enabling precise cutting, engraving, and marking. Different types of CNC laser machines are available, including CO2 lasers, fiber lasers, and Nd:YAG lasers, each with their specific applications and capabilities. These machines have revolutionized the industry by offering unparalleled precision and versatility in various manufacturing processes.

Explanation of how CNC laser machines work

CNC laser machines work by utilizing a computer-controlled system to guide a laser beam onto a material. The laser beam is directed through a series of mirrors and lenses, focusing it to a precise point. The heat generated by the laser beam interacts with the material, allowing for cutting, engraving, and marking. The computer system controls the movement of the laser beam, ensuring precise and accurate results. CNC laser machines use various laser types, such as CO2 lasers, fiber lasers, and Nd:YAG lasers, each with their specific applications and capabilities. These machines have revolutionized manufacturing processes by providing unparalleled precision and versatility.

Different types of CNC laser machines available in the market

There are several different types of CNC laser machines available in the market, each with its own unique capabilities and applications. Some common types include CO2 lasers, which are versatile and widely used for cutting and engraving a variety of materials. Fiber lasers are known for their high speed and precision, making them ideal for metal cutting. Nd:YAG lasers are often used for marking and engraving metals and plastics. Each type of CNC laser machine offers specific advantages and is suited for different manufacturing needs.

Applications of CNC Laser Machines

CNC laser machines are used in a wide range of industries for various applications. In the automotive industry, they are utilized for precise cutting and welding of metal parts. In the electronics industry, CNC laser machines are used for PCB manufacturing and precision cutting of components. They are also used in the medical field for surgical procedures and in the architecture industry for intricate model making. CNC laser machines have also found applications in the signage, jewelry, and aerospace industries. Their versatility and precision make them indispensable in modern manufacturing processes.

Various industries benefiting from CNC laser machines

The versatility of CNC laser machines has led to their widespread adoption in various industries. In the automotive industry, these machines are used for precise cutting and welding of metal parts. In the electronics industry, CNC laser machines are essential for PCB manufacturing and precision cutting of components. They are also utilized in the medical field for surgical procedures and in the architecture industry for intricate model making. Additionally, CNC laser machines have applications in signage, jewelry, and aerospace industries. Their ability to handle a wide range of materials makes them indispensable in modern manufacturing processes.

Examples of products created using CNC laser machines

CNC laser machines have revolutionized product manufacturing across industries. These machines are capable of creating intricate and precise designs on a wide range of materials. Some examples of products created using CNC laser machines include metal components for electronic devices, wooden furniture with intricate designs, acrylic signage, stainless steel cutlery, and even delicate jewelry pieces. The versatility of CNC laser machines allows for the production of high-quality and customized products in various industries.

Benefits of CNC Laser Machines

CNC laser machines offer a multitude of benefits in the manufacturing industry. These machines provide improved precision and accuracy in the production process, allowing for intricate and detailed designs. The use of CNC laser machines also enhances productivity and efficiency, reducing manufacturing time and costs. With their versatility and high-quality output, CNC laser machines are revolutionizing the industry.

Improved precision and accuracy in manufacturing

CNC laser machines have revolutionized the manufacturing industry by offering improved precision and accuracy in the production process. With their advanced technology and computer-controlled systems, these machines can execute intricate and detailed designs with utmost precision. They can consistently produce high-quality output, eliminating human errors and ensuring product consistency. This level of precision allows manufacturers to meet strict quality standards and deliver flawless products to their customers. CNC laser machines also enable the production of complex shapes and contours that would be challenging and time-consuming to achieve manually. By utilizing laser technology, these machines can achieve extremely fine cuts, resulting in smooth and precise edges. This level of accuracy is invaluable in industries that require intricate designs, such as aerospace, electronics, and jewelry manufacturing. With CNC laser machines, manufacturers can confidently produce products with exceptional precision, providing a competitive edge in the market.

Enhanced productivity and efficiency in production processes

CNC laser machines have significantly improved productivity and efficiency in manufacturing processes. These machines can operate continuously, 24/7, with minimal downtime, resulting in increased productivity. They can also execute complex designs and intricate cuts at a faster speed than traditional methods, reducing production time. Additionally, CNC laser machines are equipped with automated features and software integration, streamlining the production process and minimizing manual labor. These advancements enhance overall efficiency, allowing manufacturers to produce more products in less time and with fewer resources.

Advancements in CNC Laser Technology

Advancements in CNC laser technology have revolutionized the manufacturing industry. Modern CNC laser machines now boast innovative features such as higher power output, improved accuracy, and faster cutting speeds. They also incorporate advanced software integration, allowing for seamless connectivity with other manufacturing processes. Additionally, new developments in cooling systems and automation have further enhanced the efficiency and reliability of CNC laser machines, making them an indispensable tool for modern manufacturing.

Innovations and new features in modern CNC laser machines

Modern CNC laser machines have seen significant advancements and innovations that have transformed the manufacturing industry. These machines now offer higher power output, improved accuracy, and faster cutting speeds. They also come equipped with advanced software integration, allowing for seamless connectivity with other manufacturing processes. Furthermore, advancements in cooling systems and automation have enhanced the efficiency and reliability of CNC laser machines, making them indispensable tools for modern manufacturing.

Integration of CNC laser machines with other technologies

Integration of CNC laser machines with other technologies has revolutionized the manufacturing industry. These machines can now seamlessly connect with computer-aided design (CAD) software, allowing for precise and automated cutting processes. Additionally, CNC laser machines can be integrated with robotics systems, enabling unmanned operations and further increasing productivity. The integration of these technologies enhances accuracy, efficiency, and overall performance of CNC laser machines in manufacturing processes.

Future of CNC Laser Machines

The future of CNC laser machines is filled with potential developments and advancements in the industry. As technology continues to evolve, we can expect to see improvements in laser power, cutting speeds, and automation capabilities. Additionally, new materials and design functionalities will expand the applications of CNC laser machines even further. With these advancements, CNC laser machines will continue to reshape the industry and play a crucial role in manufacturing processes.

Potential developments and advancements in the industry

Potential developments and advancements in the CNC laser machine industry are expected to focus on improving laser power and cutting speeds, as well as enhancing automation capabilities. New materials and design functionalities will also be explored, expanding the potential applications of CNC laser machines. These advancements will revolutionize manufacturing processes, offering increased precision, efficiency, and versatility across various industries. The future of CNC laser machines holds immense promise for transforming the manufacturing landscape.

Conclusion on the impact of CNC laser machines in shaping the future of manufacturing

In conclusion, CNC laser machines have had a profound impact on the manufacturing industry, revolutionizing production processes and enabling the creation of intricate and precise designs. With their ability to enhance productivity, efficiency, and accuracy, CNC laser machines are set to play a crucial role in shaping the future of manufacturing. As advancements continue to be made in laser technology and automation capabilities, the potential for further innovation and expanded applications is immense. The future of manufacturing looks promising with CNC laser machines at the forefront.