CNC Laser Cutting Machines

CNC and laser cutting machines are both widely used in the manufacturing industry for precision cutting. CNC cutting machines use computer numerical control to guide the cutting process, while laser cutting machines use a high-powered laser beam to melt, burn, or vaporize materials. These machines offer different advantages and are suitable for various applications. Understanding the differences between CNC and laser cutting machines is crucial in choosing the right one for specific projects and industries.

I Overview of CNC Cutting Machine

CNC cutting machines, also known as computer numerical control cutting machines, are widely used in the manufacturing industry for precision cutting. These machines are guided by computer software programs, which control the movement of the cutting tools and dictate the shape and size of the cut. CNC cutting machines are highly accurate and can cut through a wide range of materials including metals, plastics, wood, and composites. They are commonly used in industries such as automotive, aerospace, and furniture manufacturing. CNC cutting machines offer precise and repeatable cutting, making them ideal for complex and intricate designs.

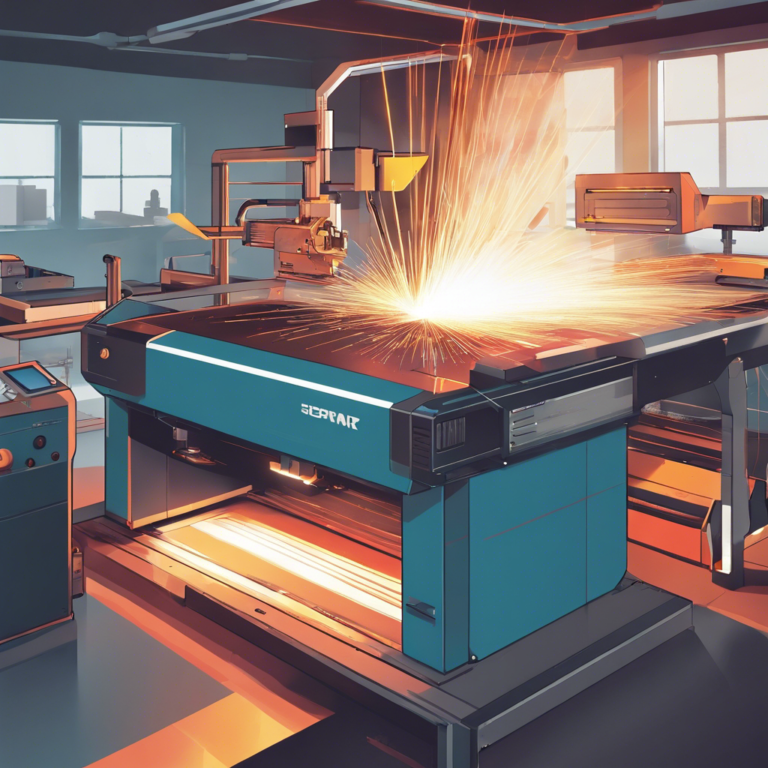

II Overview of Laser Cutting Machine

Laser cutting machines utilize a high-powered laser beam to cut through various materials with precision. These machines work by directing the laser beam onto the material’s surface, which melts, burns, or vaporizes the material. The laser cutting process is controlled by computer software, allowing for intricate designs and shapes to be cut accurately. Laser cutting machines are commonly used in industries such as automotive, aerospace, and electronics manufacturing due to their high accuracy and versatility.

Operating Principles of CNC and Laser Cutting Machines

CNC cutting machines operate by using a computer-controlled system to guide the cutting tool along a predetermined path. The CNC software generates the cutting path based on the design input. On the other hand, laser cutting machines use a high-powered laser beam directed by computer software to melt, burn, or vaporize the material. The laser beam is guided along the cutting path, ensuring precise and accurate cuts. Both machines offer precise control over the cutting process, but the underlying principles differ significantly.

I How CNC Cutting Machines Work

CNC cutting machines work by following a computer-generated cutting path. The CNC software translates the design into precise instructions for the cutting tool. The machine moves the cutting tool along the programmed path, using motors and drive systems. The cutting tool cuts, shapes, or perforates the material with accuracy and precision. CNC machines offer flexibility and can accommodate various cutting tools for different materials and designs.

II How Laser Cutting Machines Work

Laser cutting machines utilize a high-powered laser beam to cut through materials. The laser beam is directed onto the material, melting or vaporizing it at the focused point. The laser moves along the programmed path, guided by a computer-controlled system. The laser’s intensity and duration can be adjusted to achieve different cutting effects. Laser cutting machines offer precise and clean cuts, making them ideal for intricate designs and delicate materials.

Key Differences in Precision and Versatility

When it comes to precision, CNC cutting machines offer high accuracy due to their precise movements and controlled cutting paths. They are ideal for achieving intricate details in designs. On the other hand, laser cutting machines provide even greater precision, capable of cutting intricate patterns with utmost accuracy. Laser cutting machines also offer more versatility as they can cut a wide range of materials, including metals, plastics, and fabrics, while CNC cutting machines are limited to certain materials only. Therefore, if precision and versatility are key factors, laser cutting machines are the preferred choice.

I Precision in CNC Cutting Machines

Precision in CNC cutting machines is achieved through their precise movements and controlled cutting paths. These machines offer high accuracy, allowing for the creation of intricate and detailed designs. With the ability to follow programmed instructions precisely, CNC cutting machines cut materials with consistent precision. This makes them ideal for industries that require precise and accurate cuts, such as automotive, aerospace, and electronics manufacturing.

II Precision in Laser Cutting Machines

Laser cutting machines offer exceptional precision in cutting various materials. The focused laser beam enables accurate and intricate cuts, allowing for the creation of detailed designs. Laser cutting machines are known for their high level of accuracy, with the ability to achieve precision as fine as 0.1 mm. This makes them ideal for applications that require intricate and precise cuts, such as in the jewelry, signage, and architectural industries. Additionally, laser cutting machines have a narrow kerf width, resulting in minimal material wastage and precise cuts without any distortion.

Material Compatibility and Thickness

Laser cutting machines are known for their wide range of material compatibility. They can easily cut through various materials such as metal, wood, plastic, fabric, and acrylic. Laser cutting machines can handle different thicknesses, ranging from thin materials like paper to thick materials like steel. On the other hand, CNC cutting machines are more suitable for materials like metal, wood, and plastic. The thickness capacity of CNC cutting machines may vary depending on the specific machine model and power.

I Materials Compatible with CNC Cutting Machines

CNC cutting machines are compatible with a wide range of materials, including metal, wood, plastic, foam, and composite materials. They can handle different thicknesses, ranging from thin sheets to thick blocks. The versatility of CNC cutting machines allows for precise and clean cuts in various materials, making them suitable for industries such as automotive, aerospace, and furniture manufacturing.

II Materials Compatible with Laser Cutting Machines

Laser cutting machines are capable of cutting a wide range of materials, including metal, wood, plastic, acrylic, leather, fabric, and more. They are particularly well-suited for materials that are sensitive to high temperatures or require intricate and detailed cuts. Laser cutting machines can handle varying thicknesses, providing versatility in material choices for different industries and applications.

Speed and Efficiency in Production

When it comes to speed and efficiency in production, laser cutting machines typically have the upper hand. Laser cutting machines can operate at high speeds and are capable of completing intricate cuts with precision and accuracy. They have minimal setup time and can be easily programmed to cut multiple pieces in one run, optimizing production efficiency. CNC cutting machines, on the other hand, may require more setup time and have slightly slower cutting speeds compared to laser cutting machines.

I Speed of CNC Cutting Machines

CNC cutting machines have a relatively fast cutting speed, although it may be slightly slower compared to laser cutting machines. The speed of CNC cutting machines depends on factors such as the complexity of the design and the material being cut. However, CNC cutting machines still offer a high level of efficiency and productivity, making them suitable for various manufacturing and fabrication industries.

II Speed of Laser Cutting Machines

Laser cutting machines are known for their high cutting speed, making them ideal for industries that require quick and efficient production. The speed of laser cutting machines depends on various factors, such as the power of the laser, the material being cut, and the complexity of the design. With their ability to rapidly cut through a wide range of materials, laser cutting machines can significantly increase productivity and reduce production time.

Conclusion and Which to Choose

In conclusion, the choice between CNC and laser cutting machines ultimately depends on the specific needs of the industry and the materials being cut. CNC cutting machines offer high precision and versatility for complex designs, while laser cutting machines excel in speed and efficiency. Consider factors such as material compatibility, desired precision levels, and production speed to make the best decision for your business.

I Factors to Consider When Choosing Between CNC and Laser Cutting Machines

When choosing between CNC and laser cutting machines, there are several important factors to consider. These include the desired precision level for the cutting project, the types of materials that will be cut, the production speed requirements, and the overall budget. It is also crucial to evaluate the specific capabilities and features of each machine to ensure they align with the needs of the business or industry. By carefully considering these factors, businesses can make an informed decision on whether a CNC cutting machine or a laser cutting machine is the best choice for their cutting applications.

II Applications and Industries Best Suited for CNC and Laser Cutting Machines

CNC cutting machines are widely used in industries such as automotive, aerospace, and construction for precise cutting of materials like metal, wood, and plastics. They are ideal for applications that require complex shapes and high accuracy. On the other hand, laser cutting machines are commonly utilized in industries such as signage, electronics, and jewelry for precise and intricate cutting of materials like acrylic, glass, and metals. Their ability to cut intricate patterns and high-speed capabilities make them perfect for these industries.