Here is a bit more about the other cnc routers that use the same or similar components.

Mine is an 1610Pro.

1310, 1610, 1810, 2418 or 3018?

1810 refers to the 18cm x 10cm cutting bed, and so on.

Many of them come in ‘Pro’ versions where black 10mm machined plastic (‘Bakelite’, according to the manufacturer) x-gantry support uprights and y-axis end plates replace aluminium extrusions in the non-pro versions. For some reason, the Pro version of the 1810 is called the 1610Pro.

Engineer in Wonderland cnc-related blogs are indexed here

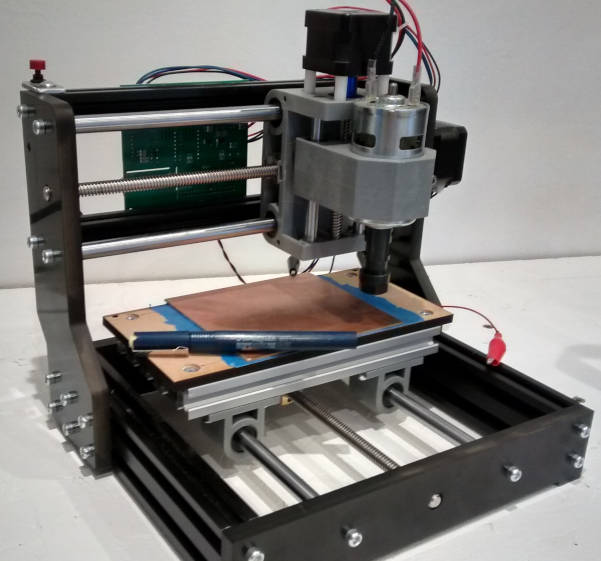

They all use the same basic construction, with both the y-axis (front-back, carrying the workpiece) and x-axis (side-to-side) gantry fixed solidly to the frame (see photo), while the z-axis (up and down, carrying the tool) slides on the x-axis.

Other sizes available in this format are 2418 and 3018 – the latter being the most popular.

All share similar parts and the larger sizes are not beefed-up, and so are more flexible. The 1310 is an exception, being all-aluminium and beefed-up – it is a little jewel.

Interrupt for SMEs: I would say a 3d printer is an easily-learned low-cost way of quickly making fixtures, brackets and prototype enclosures or few-off production enclosures. Cnc routers are not there yet – reasonable ones cost a lot more and free cnc software is not so easily learned.

Update 2024: cnc software has improved, but is still not up to the standard of free 3d printing software (although thanks to all the developers, is is all amazing), good desktop cncs are now available – take a look at the Genmitsu 3030-Prover Max, which I would get if I was starting out now.

EndInterrupt

Bed dimension derived names have have become largely synonymous with machine types – thus all 1810s and 3018s (I have seen) have the same fixed x-gantry and axis.

A randomly-picked example of a 2030, from Dowin Technology via Alibaba.

A randomly-picked example of a 2030, from Dowin Technology via Alibaba.

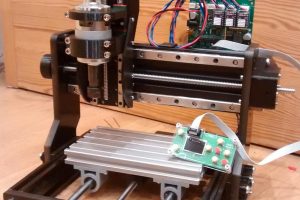

Another format of machine (example left) has the bed fixed to the frame, with the y-axis sliding the x-gantry fore and aft. These tend to be in the next price bracket up and include the (rare) 1419, the 2030 and the 3040.

This is the format that then goes right up to routers that will cut an 8 x 6′ sheet of plywood (that’s 2.4 x 1.2m).

None of these is solid enough to qualify as a milling machine (I have no idea where the definitions of milling and routing crosses over).

I am going to stick with typing about the lower-end 1810 3018 style that I have at least some experience with.

And mine has proved a great machine with which to approach the cnc learning curve – with little consequence when the wrong commands are executed (as will almost inevitably happen) as the stepper motors are not strong – so no lost fingers or bent steel.

That said, I have a mounting pile of broken cutter bits, mostly through stuffing them into the work-holding bed – just a warning here, pcb copper cutting bits have sharp brittle needle-like ends that can ping off into space if you break them sideways, so wear eye protection.

Bargain cnc machine shortcomings quickly become apparent as fledgling operator confusion begins to clear.

Not really noticed when cutting soft materials – which is what they are intended to do – limitations include inaccuracy and chattering (cutter resonance) due to slack and flexing (noticed with hand pressure on the motor) in the x-axis (high bars running left to right in the top photo) and z-axis (bars running up and down behind the motor).

Ways to reduce flex and slack

Flex is not as bad in 1610/1810 compared with 3018 as the 10mm diameter x-rods are only 240mm long between supports, while they are still 10mm in 3018s, but ~360mm long.

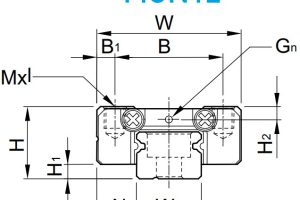

Next comes the cylindrical bearings that run on those rods. Tolerance in rods, bearings and housings mean that there is often slack between rod and bearing, as well as between bearing and housing.

There is a similar situation on the z-axis, except the rods (8mm dia) are far shorter and less likely to bend.

Swapping-in better bearings and rods is one way people get rid of some of this slack, and 3d printing a new z-assembly plastic parts can get rid of the housing slack in various ways.

While 3d printing that assembly, some take the opportunity to re-design the parts to accept stiffer 12mm or 16mm x-rods and 10mm z-rods.

The 12mm x-rod mod is pretty straight forward, and 16mm is ok on non-pro cncs, but going to 16mm on pro versions requires making new side plates due to the proximity of the rods and the aluminium profile that runs across behind them stiffening the side plates (just about visible in the top photo – the rectangular part right at the back is the control board). Update – there might just be room on mine…. await with bated breadth….

A note on structural stiffness

I am no mechanical engineer (so please correct me if I am wrong), but I had a quick look at some equations and it looks like the deflection in a solid rod from sideways force drops with the 4th power of radius and increases with the cube of length.

This means (if I have worked it out correctly) that going to 12mm rods in a 1810 reduces absolute x-deflection to the same amount as 16mm rods in a 3018 (~2x in both cases). That said, even 16mm rods in a 3018 are considered too flexible by some trying to cut aluminium accurately (none of these machines are designed to cut any metal – except the foil on pcbs. Caveat 1310).

Relative lateral stiffness of different diameter rods of the same length – according to a non-mechanical-engineer, please correct me if I am wrong

| Rod diameter | calculate | Relative stiffness | Deflection relative to 10mm |

| 8mm | 44 | 256 | x2.4 |

| 10mm | 54 | 625 | x1 |

| 12mm | 64 | 1,296 | x0.48 (so 1/2) |

| 16mm | 84 | 4,096 | x0.15 (so 1/6.5) |

Relative lateral stiffness of different length rods of the same diameter, same low-knowledge caveat

| Estimated rod length | calculate | Relative stiffness | Deflection relative to 240mm |

| 360mm (3018) | 1/0.363 | 21 | x3.4 |

| 300mm (2418) | 1/0.33 | 37 | x2 |

| 240mm (1810/1610Pro) | 1/0.243 | 72 | x1 |

| 190mm (1310, below) | 1/0.193 | 146 | x0.5 |

So small machines with thick rods are exponentially stiffer.

If I could make new plates (the accurately counter-bored bearing holder is stopping me), the first thing I would try would be 16mm x-rods and 10mm z-rods. Update – they might just fit without drilling on my mine – there are subtle differences between some machines, eg 68 or 72mm intra-rod spacing on x-axis.

1310, a classier machine (photo via cnc1310.ru)

1310, a classier machine (photo via cnc1310.ru)

Far less commonly known, there is a smaller ‘1310’ class (126 x 88mm bed) of cnc with superior bearing retention and superior just-about-everything-else. Combined with their shorter length (190mm, I estimate) its x-rods should deflect half as much as a 12mm-modified 1810 – or 12x less as an unmodified 3018 (see tables above). Check out this website from someone who uses a 1310 and fixed a design flaw in his.

On the subject of flaws, delivered frame parts quality is apparently not always perfect. In the UK, a great little company called Oozenest provides cut-to-length (+/-0.2mm) aluminium extrusions and will pre-tap the ends.

Russian makers seem particularly fond of these, and this website has a lot of information (top left for English translation).

These cylindrical rod machines are always red in colour, and both cut aluminium and seem to work within 0.1mm.

Update: That said, the YouTuber at Design prototype Test couldn’t get his to cut aluminium well (he is a skilled (if sometimes grumpy) product designer) – though with full-width cuts, no lubrication and maybe sticky aluminium.

And many people have got modified 3018s to cut acceptably – for example, just after I wrote the bulk of this blog, the thorough careful guy at Teaching Tech made some thin aluminium parts to his satisfaction with a lot of mods but standard 10mmm rails – btw, looks like a Dremel makes a nice low-cost spindle up-grade.

A blue version of red 1310s that uses (nominally superior) supported rectangular linear rails for motion instead of unsupported round rails has recently appeared – which looks interesting, although the design is just asking for muck to fall into the y-axis rails and jam them.

In retrospect, had I know I would enjoy cnc machining as I do, I would have initially bought a red (or, jury out, blue) 1310 and thought about replacing the ‘775’ spindle motor (~100W, 6,000rpm long 5mm shaft) with a Longdaio LD42WS-250W brushless motor (250W 12,0000rpm, short 8mm shaft) – which would have been around £500 initial outlay for a small fairy rigid machine. Here is a video of someone testing just such a combination here.

For that money, a 2030 or 3040 machine could be bought, which is a step up in mechanics with a static bed, a sliding x-gantry and supported rails – but these take up so much more room and I only make small things.

There are also non-copycat machines that seem unique to certain companies – so do search around.

Leadscrews and backlash

1810 machines and their close cousins use 8mm ‘two-start’ (so 4mm travel per revolution ‘T8x4) acme lead screws driven by NEMA 17 size stepper motors.

That is the same size (42 x 42mm) stepper as most 3d printers, but most 3d printers use T8x8 (8mm per turn, ‘four-start) leadscrews for their z-axes. T8x2 (‘one-start’, 2mm per turn) lead screws also exist.

T8x4 is the least common leadscrew in hobby/maker use, and one for which there is restricted anti-backlash nut choice.

The ones in 1810 machines have relatively weak pre-load springs (because they have relatively weak motors that might not deal with all the friction associated with stiffer-sprung nuts) and there will therefore always be some spring-loaded slop in each axis once the cutting force overcomes the spring.

I cannot find any non-sprung adjustable anti-backlash blocks of the OpenBuilds form (photo left, via Oozenest) with T8x4 threading, so to remove this source of slop requires stronger springs with careful lubrication, moving to a no-backlash ‘ballscrew’, or more thought.

I cannot find any non-sprung adjustable anti-backlash blocks of the OpenBuilds form (photo left, via Oozenest) with T8x4 threading, so to remove this source of slop requires stronger springs with careful lubrication, moving to a no-backlash ‘ballscrew’, or more thought.

Another source of backlash is the lack of longitudinal leadscrew restraint – nothing stops the leadscrews moving longitudinally except the motor coupler and the springs inside the motor – not a bad solution for a lightly-loaded 3d printer, but not great for cutting tool force.

Commercial linear actuators have a thrust bearing at one end of the leadscrew (or even both ends of the leadscrew) to transfer longitudinal force into the machine frame. This can easily be achieved with a couple of cheap thrust bearings and 8mm collars at one end of each leadscrew (if long enough), and some people even get a similar effect with a strategically places washer between the motor and its coupler.

Hobby cnc routers lag hobby 3d printers

Low-end hobby cnc routers are lagging low-end hobby 3d printers: You get a far more polished 3d printer (kit or assembled) for less than £250 than you do a cnc router.

One particularly frustrating omission is axis end stops on cncs, which double as homing references and auto-travel-limiters on 3d printers. Frequently the cnc controller board has connections for them, and the software (‘grbl’) can use them, but the switches and wiring absent, allowing injudicious instructions to crash mechanisms into the frame.

Over the next year or so, I suspect cheap cnc routers will become increasingly polished – Sainsmart is already offering up-market 3018s – its 3018 prover has more aluminium and less plastic. I predict thicker guide rods will appear too.

The lag behind 3d printers can also be seen in software, with hobby/maker-grade 3d print software approaching commercial grade software in look and feel, while similar 3d router software requires far more knowledge of computers to operate.

This is not to denigrate the folk who have written all of this software – often makers have given up huge amounts of their own time to create working software, then generously open-sourced it for others to use. And why should the person who writes something that suits their needs, who then gives it away for free, have to polish it so that an idiot like me can operate it.

Ironically, I have read (but cannot vouch for its truth) that the Arduino dynamics package within the 3d printer control software Marlin, started life inside grbl cnc machine control software.

The End

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News

I’m always impressed with the things you get up to & accomplsh.

Me, on the other, finally got A Round Tuit and mounted a bench grinder and a pillar drill that I’ve owned for a mere 20 years or so onto my recently constructed work bench in my recently refurbished tin shed.

The refurbishment is an act of desperation whilst the new owners next door knock seven bells out of their half of the semi.

I do miss the quiet little old lady who used to live next door.

Hi zeitghost

You have my sympathy on neighbour noise – for reasons I am not going to put on public record here (things have improved anyway)…. I too think back to the time I lived between two old ladies.

Nice to get the shed refurbished AND the grinder and drill mounted – momentum maintained!!

I tend to go though surges – allowing some interesting stuff once some boring stuff is out of the way. This time the boring thing was decorating the back room, which took far longer than I expected (hoped?). That done, it is time to learn and play for a bit 🙂