Finding ways to outpace competitors is important. Stephen Holmes visits Guhring UK to learn how adopting digital tools in-house has reinforced its position as a market leader in precision cutting tools

Guhring is a world-class producer of precision cutting tools for manufacturing – the types of cutting and reaming tools used in CNC machines to create end-use parts for building other products.

The company offers customers a huge range of mass-produced tools, as well as custom-designed pieces built to exacting specifications. In an increasingly competitive market, the engineers at Guhring’s Specials Manufacturing Centre in Birmingham, UK, realised the company would need to innovate to maintain its position in the industry. The team initially began 3D printing polymer prototypes, which help guide customers during the design process, checking for fit and increasing buy-in on expensive or complicated projects.

Parts are designed by Guhring’s team, which works alongside customers to produce tools capable of cutting the metal of particularly demanding features, or even whole parts.

An example might be found inside the cylinder head of an automotive engine, where valve seats are round and valve guides are long and thin. Guhring’s team can develop a tool capable of machining both elements in one machining ‘touch’, dramatically reducing the time needed to produce a finished component.

After producing a 3D CAD model in Solidworks, the design is 3D printed using Guhring’s Markforged Mark Two 3D printer and shipped to the customer. With the polymer prototype, the customer can better assess its potential before committing to metal, even running it in the machine spindle along the CAM-programmed path.

Should a plastic prototype collide in error, it simply snaps – unlike a metal part, which might cause thousands of pounds worth of damage. In this situation, the design process would need to be restarted, with big implications for development times and cost. Using plastic is believed to save around six weeks of development time and the cost of producing a full-metal tool.

However, Guhring felt it could do more with its 3D printing technology. The team was already fans of the company’s Markforged Mark 2, and were fully trained in its Eiger build and process software, so they approached reseller Mark3D to find out what else was possible.

Cut it out

The steel blanks used to create custom tool bodies are painstakingly machined in multiple stages. To these, cutting tips are attached by a skilled Guhring employee, hand-braising a slither of Polycrystalline Diamond (PCD) into a machined pocket on the tool.

Mark3D proposed 3D printing a tool body in metal, using a Markforged Metal X 3D printer. The Guhring team was initially sceptical.

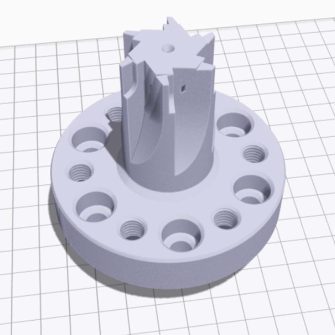

A prototype design was worked up in Solidworks, which instantly got the development team thinking. The heat generated by the machining process is what blunts tips, so in Solidworks, the team was able to place coolant channels inside the 3D-printed tool body, directing coolant onto the cutting surface in whatever configuration was needed and prolonging the life of the tool.

The pockets for the PCD tips previously had to be machined and were therefore curved. Now 3D printed as right angles, these offered much better support for the tip. Already accustomed to using the Eiger user interface for the Mark 2 3D printer, the team used it to further develop the tool design for the Metal X, assigning extra wall thicknesses where the part would need to be machined back to meet tolerances and adding a lattice infill that reduced the part weight by nearly 40%.

The prototype part was sent to be 3D printed and post processed at Mark3D on the Metal X, an FDM process that prints a green part from filament, before it is post processed and sintered.

For the Guhring prototype, the process means a 15- hour print time, followed by post processing – a 12-hour wash and four hours drying. Then, it is sintered in the benchtop Markforged oven for 27 hours, resulting in a 99.89% solid metal part.

“What’s important to remember here is that Guhring is one of the biggest sintering companies in the world,” says Mark3D managing director Ian Weston, noting that it has ovens so large that it drives forklift trucks into them. “So, when we introduced the [Markforged sinter oven] to them as a technology, they just smiled!”

With the PCD tips braised into place, it was time for testing the part on a milling machine in front of the Guhring team. The first test was over a favourable vertical cutting path – drilling down into the stock material – and it worked as well as a steel part.

Growing in confidence, they decided to pocket out a hole, putting the tool under increased sideways load, where any kicking could snap it. The tool continued to work diligently, clearing material along its path. As a final test, the operator cranked up the spindle speed as far as it would go.

Everyone was over the moon, says Weston, given that the tool survived, outperforming everyone’s expectations, and making his client the first in the world to do this with Markforged technology.

Changing opinions

All the Guhring staff still recall that first test as a groundbreaking moment. Since then, the development of further 3D-printed parts has been fast, with new benefits being unearthed.

By reducing the weight by some 40%, there’s less load on the machine tool, extending the life of the CNC machine. Tool designs previously were capable of machining 12 to 13 parts per hour now get through 40 parts and can still be returned to Guhring to be retipped with new PCD, rather than needing an entirely new tool, saving money and waste.

The H13 tool steel printed on the Metal X comes out of the oven case-hardened, and early reports from customers suggest that it lasts longer than machined and heat-treated steels.

The ability to 3D print tools with more freedom means that designs have become more elaborate. This includes an incredible design for a drill that, due to a hollow drum through its centre, automatically ejects the swarf as it cuts it from inside of an engine cylinder.

Despite what appears on paper to be a long post processing methodology to realise the final parts, compared with traditional manufacturing, lead times have dropped from over six weeks for a new tool, down to a week or two.

Equally, R&D work is less costly and less error-prone, giving the team confidence to try out new ideas.

Guhring’s custom work is winning back old clients and drawing the attention of new ones, while helping increase the visibility of the company’s existing products and services across the board – all thanks to its team being willing to pioneer a new technology to gain a cutting edge.