The two-stroke engine has been used in a variety of applications, including light aircraft, motorcycles, chainsaws, outboard motors, and power generation. Despite being largely replaced by four-stroke engines, the future of the two-stroke engine could have big benefits in hybrid vehicles and their production.

The two-stroke engine was designed roughly 140 years ago. The simple design and high power-to-weight ratio of the two-stroke engine are well-known. However, because these engines lubricate with a mixture of fuel and two-cycle oil, their emissions are higher than usual. Two-stroke engines have been phased out in favor of four-stroke engines, which are more sophisticated designs with lower emissions because the gasoline and oil are not combined.

Due to its excellent qualities of high power-to-weight ratio, as well as safe fuel storage and transportation, the two-stroke diesel engine has been widely used as the power system in unmanned aerial vehicles and general aviation aircrafts. Furthermore, it has sufficient power density at low crankshaft speeds, allowing for direct connection to the propeller without the use of a speed reducer. Due to this, the two-stroke engine continues to fascinate engineers because of its fuel economy, high power output, and clean emissions. Because of these optimal performance characteristics, the engine is on the threshold of new development, as car makers worldwide seek to utilize technology resulting from two-stroke engine research in new applications.

As the name implies, the two-stroke engine only requires two piston movements (one cycle) in order to generate power. The engine is able to produce power after one cycle because the exhaust and intake of the gas occurs simultaneously. Due to shifting pressures, a valve for the intake stroke opens and closes. Furthermore, because the fuel comes into contact with moving components frequently, it is combined with oil to offer lubrication, allowing for smoother strokes.

Two-stroke engines are lighter, more efficient, can utilize lower-grade gasoline, and are more cost-effective than four-stroke engines. As a result, lighter engines have a higher power-to-weight ratio (more power for less weight). They don’t have the mobility of four-stroke engines, and they require more lubrication. This makes two-stroke engines suitable for ships (which must transport a large amount of cargo), motorcycles, and lawn mowers, whereas four-stroke engines are best for cars and trucks.

The thermal efficiency of these gasoline engines varies depending on the vehicle’s model and design. In general, gasoline engines convert 20% of the fuel (chemical) energy to mechanical energy, with only 15% being used to move the wheels (the rest is lost to friction and other mechanical elements).

The initial advantage of a two-stroke engine is the double cycle frequency, which allows the designer to either design a very compact and light unit for a given power target, or limit the maximum rotational speed, resulting in mechanical efficiency, noise and vibration advantages. Unlike rotary engines, a two-stroke engine and a four-stroke engine can easily share many technologies and components. On the two-stroke, in particular, a normal automotive Gasoline Direct Injection (GDI) system can be used if the maximum engine speeds are equivalent. The injector’s position and nozzle geometry, of course, must be carefully developed for the specific purpose. The two-stroke engine can address most of the common difficulties with fuel economy and pollution thanks to direct injection.

First, gasoline can be injected after the exhaust port has closed, preventing any loss and emissions. Furthermore, because of the high turbulence level, the compactness of the chamber, and the injector capability to generate adequate charge stratification, a two-stroke GDI engine may run on a lean/stratified mixture with a relatively significant number of residuals at low load and speed. As a result, all raw pollutant emissions can be drastically reduced, while fuel efficiency can be enhanced over typical partial load operations (which are punished by induction throttling).

A two-stroke engine and a Spark Ignition (SI) passenger automobile engine can readily share many technologies and components. The lubrication system (oil sump, pump, internal channels) can be the same if the crankcase pump is removed. Furthermore, a two-stroke can be equipped with a commercial high-pressure GDI system. Finally, a two-stroke prototype can be built using an existing four-stroke and merely changing the valve actuation approach, as several researchers have done.

Two-stroke engines were notorious for their poor fuel economy and for releasing emissions and pollution in the past. However, that typical two-stroke engine archetype has evolved dramatically in the previous decade. The majority of huge gas guzzling two-stroke engines have been replaced with direct injection and fuel injected two-stroke engines. These new engines are cutting-edge, consuming less gasoline, yet producing more power.

While two-stroke engines were inferior to four-stroke engines in several categories, there was one area where the two-stroke engine excelled. Because of its simpler construction, two-stroke engines are more reliable. Owners who take excellent care of their two-stroke engine will have an engine that will last a long time. The new two-stroke engines are as dependable as their predecessors. The new direct injected and fuel injected two-stroke engines use a metered supply of two-stroke oil to lube all the rings and bearings, keeping the engine in good shape while boosting fuel economy.

Hybrid vehicles and other applications

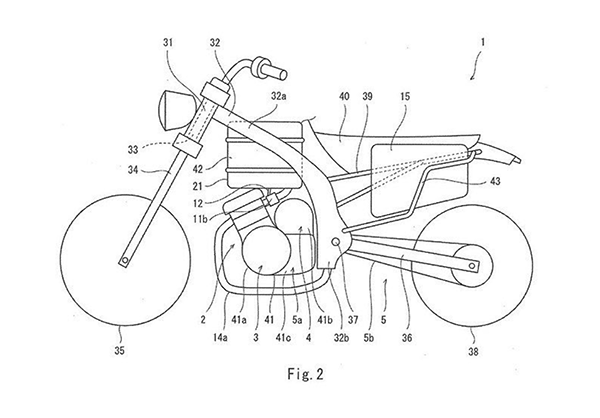

One area where two-stroke engines could be very beneficial is within hybrid vehicles. Kawasaki is on the verge of releasing a hybrid two-stroke motorcycle. Kawasaki is developing an electric motorcycle with a manual transmission. This motorcycle’s patent is currently being worked on and shows that Kawasaki is developing a series hybrid. The majority of hybrid automobiles, such as the Prius, are “parallel hybrids,” meaning they use a combination of gasoline and electric power. However, a series hybrid, like the Chevrolet Volt or BMW i3, is basically an EV that uses a gasoline engine to recharge its batteries. The patent diagram for the hybrid motorcycle is shown in Figure 2.

The series-hybrid vehicles eliminate one of the most significant drawbacks of electric passenger cars – their restricted autonomy. These vehicles are particularly well suited to urban (often in full electric mode) and suburban (autonomy backed by an internal combustion engine, commonly known as Range Extender, RE) missions, as well as programmable missions that include the ability to charge the batteries via the grid (plug-in hybrid).

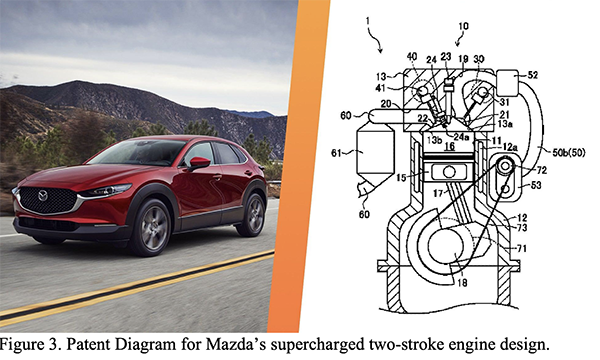

Over the last 50 years or more, two-stroke engines have steadily declined in popularity. While they have higher power-to-weight ratios and are frequently technically simpler than four-stroke rivals, they also have higher emissions and limited power bands. Mazda, on the other hand, finds value in the technology and has patented a new supercharged two-stroke engine design, as users of the New Nissan Z forums have discovered. The design is based on Mazda’s Skyactiv X technology and promises “increased fuel economy,” though it’s unclear to what extent it has improved.

The company’s current four-stroke engine uses an advanced spark-controlled compression ignition regime to run the engine with a leaner fuel-air mixture for improved efficiency, while traditional spark ignition is retained for high-load, high-power operation, where compression ignition becomes more unstable. The same concept is implemented in this two-stroke design, which aims to run in compression-ignition mode for efficiency while switching to spark ignition at larger engine loads.

Prospects

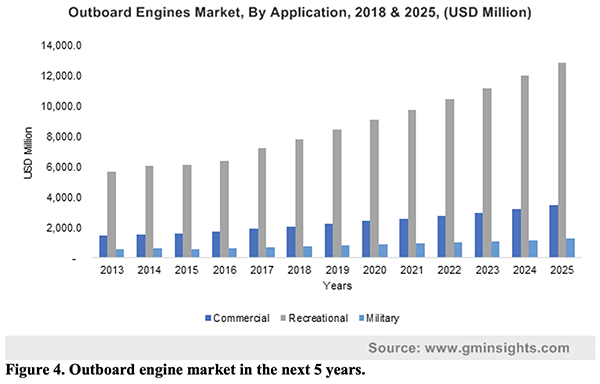

By 2027, the market for two-stroke outboard engines is expected to be worth more than $3 billion. The growing popularity of two-stroke engines can be directly linked to functional advantages over four-stroke engines, such as reduced weight, higher torque output, lower maintenance costs, and a better power-to-weight ratio. Recent developments in engine technology have also played a role in the increased popularity of two-stroke engines. To make use of two-stroke technology’s possibilities, manufacturers are continually investigating and experimenting with it.

To summarize, two-stroke engines offer several advantages, particularly when it comes to trail riding, where their modest weight is a significant benefit. Regardless of efficiency, fuel economy, or emissions, more automakers are attempting to include two-stroke engines, and they should become more widespread in the next few years.

About the Authors

Dr. Raj Shah is a director at Koehler Instrument Company in New York, where he has worked for 27 years. He is also an elected Fellow by his peers.

Daisy Ann Norman is a chemical engineering student from SUNY, Stony Brook University. She is also part of a growing internship program at Koehler Instrument Company in Holtsville, NY, exploring opportunities in the field of alternative energy.